Contemporary operational systems are frequently exposed to demanding conditions such as vibrations, cyclic loads, and thermal variations. Ensuring reliable sealing amidst these dynamic stresses is essential for operational continuity, safety, and efficiency. While traditional gaskets may falter, spiral wound gaskets offer a distinctive blend of flexibility, strength, and adaptability, making them a favoured choice for systems that encounter varying pressures, temperatures, and mechanical stress. This guide delves into the functionality of spiral wound gaskets, their superiority in dynamic conditions, and the selection, installation, and maintenance practices that enhance their performance.

The challenges dynamic conditions pose to sealing

Sealing systems endure ongoing mechanical and thermal stress in dynamic operational settings. Vibrations from equipment movement, cyclic changes in pressure and temperature, and thermal expansion or contraction can jeopardize conventional gaskets, often leading to premature failure. Even slight leakage can result in inefficiencies, heightened maintenance needs, environmental hazards, and diminished overall system reliability, impacting both safety and productivity. Spiral wound gaskets are specifically designed to tackle these persistent issues. Their unique construction enables them to absorb mechanical stresses, sustain consistent compression, and adjust to varying operational conditions. This ensures reliable sealing performance even in demanding environments, making them a preferred choice in industries where conventional gaskets frequently fail.

How spiral wound gaskets work

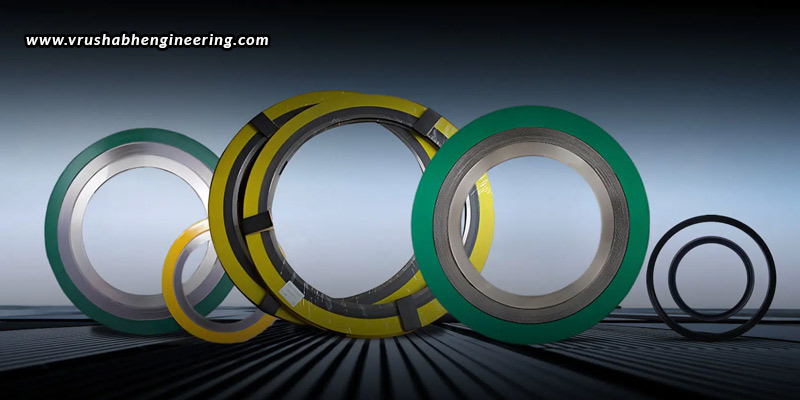

Spiral wound gaskets are semi-metallic sealing devices made up of alternating layers of metal and filler material arranged in a spiral formation. This design merges structural integrity with flexibility, allowing the gasket to adapt to flange surfaces and accommodate system movements.

Key components

- Metal windings: These provide mechanical strength and function like a spring, enabling the gasket to compress and return to its original shape under pressure.

- Filler material: This component is soft and compressible, allowing it to fit into micro-imperfections on flange surfaces, thus ensuring a leak-proof seal.

- Inner and outer rings: These components improve centring, prevent excessive compression, and offer blowout protection.

The integration of metal and filler materials enables spiral wound gaskets to sustain consistent sealing pressure while adjusting to thermal and mechanical changes.

Material selections for spiral wound gaskets

One of the key advantages of spiral wound gaskets is their capacity to customize materials as per specific operational requirements.

Metal winding options

- Stainless steel for its resistance to corrosion and high strength

- Nickel alloys for environments with elevated temperatures

- Carbon steel for typical conditions

Filler material options

- Graphite for high-temperature applications and chemical resistance

- Engineered composites tailored for particular operational demands

- PTFE for robust chemical resistance

Design configurations

- Without rings for low-pressure scenarios where controlled compression is adequate

- Outer ring only helps in centring and restricts compression to avoid extrusion

- Inner ring only improves overall stability and effectively safeguards against inward buckling

- Both rings: Optimizes stability, load distribution, and resistance to blowouts

Customizing the gasket’s materials and design guarantees dependable performance under conditions of vibration, cyclic loads, and thermal expansion. For industries seeking high-quality spiral wound gaskets, Vrushabh Engineering is recognized as a top spiral gasket manufacturer in India, providing precision-engineered spiral wound gaskets that deliver reliability, durability, and consistent sealing performance in dynamic operating environments.

Resilience under dynamic conditions

Sealing systems face multiple challenges in dynamic environments, including vibration, cyclic loads, and thermal fluctuations. Understanding how spiral wound gaskets respond to these stresses highlights their ability to maintain reliable performance, prevent leaks, and ensure long-term operational stability.

- Managing vibration

Vibration significantly contributes to gasket failure in dynamic systems, as ongoing mechanical stress can loosen fasteners, distort gaskets, and create micro-gaps that result in leakage. Spiral wound gaskets are engineered to tackle these issues. Their spiral design functions like a spring, absorbing vibrations and reducing stress on the sealing surface, while the metal layers sustain compressive force even amidst repeated mechanical disturbances. Simultaneously, the compressible filler material allows for minor movements without jeopardizing the seal. This combination of attributes offers outstanding vibration resistance, guaranteeing dependable performance and minimizing the likelihood of leaks in settings with constant mechanical movement.

- Enduring cyclic loads

Cyclic loads arise when systems undergo repeated fluctuations in pressure, temperature, or mechanical stress, often causing traditional gaskets to deform, crack, or extrude, leading to leakage and system downtime. Spiral wound gaskets effectively address these challenges with their elastic metal windings, enabling the gasket to return to its original shape after each cycle. Furthermore, compression is uniformly distributed across the flange, mitigating localized stress and averting failure. Their sturdy construction ensures long-term stability, preserving sealing integrity over thousands of cycles and delivering consistent, reliable performance even in highly variable operating conditions.

- Thermal expansion and contraction

Temperature changes lead to the expansion and contraction of flanges and sealing surfaces, potentially undermining the effectiveness of various sealing solutions. However, spiral wound gaskets are specifically designed to handle these thermal movements. Their flexible spiral structure accommodates expansion and contraction while maintaining contact with the flange surface. Furthermore, temperature-resistant fillers like graphite or PTFE ensure compressibility even at high or varying temperatures. The presence of inner and outer rings aids in evenly distributing stress, thus preventing deformation due to thermal stress. Collectively, these characteristics guarantee leak-free operation, even in systems that experience frequent thermal cycling.

Ensuring longevity with best practices for installation and maintenance

Even the most robust spiral wound gaskets can only achieve their maximum performance when they are installed and maintained correctly. Following best practices guarantees long-term reliability, leak-free functionality, and reduced downtime in systems that experience dynamic conditions.

- Best installation practices

Correct installation is vital for ensuring consistent sealing performance. Flange surfaces must be clean, flat, and undamaged to facilitate even compression. Bolts should be tightened in a cross-pattern to the specified torque to ensure uniform load distribution across the gasket. Furthermore, the gasket must be precisely aligned with the flange to avoid extrusion or uneven stress. Adhering to these installation guidelines enhances the gasket’s capacity to endure vibration, cyclic loads, and thermal expansion, thereby ensuring dependable and long-lasting operation.

- Maintenance considerations

Regular maintenance is crucial for maintaining gasket performance and preventing unforeseen failures. Routine inspections should be performed to identify any signs of deformation, wear, or leakage. Verifying torque helps sustain uniform compression, and gaskets showing signs of fatigue, cracking, or filler extrusion should be replaced without delay. Proper storage before installation, away from contaminants or potential physical damage, further safeguards the gasket. By establishing a systematic maintenance program, the lifespan of spiral wound gaskets can be prolonged, operational downtime minimized, and consistent sealing performance assured.

Spiral wound gaskets represent a highly advanced solution for dynamic operating conditions, delivering dependable sealing amidst vibration, cyclic loads, and thermal variations. Their distinctive spiral design, versatile materials, and customizable configuration enable them to uphold integrity where other gaskets may falter. By integrating appropriate material choices, optimal installation techniques, and regular maintenance, spiral wound gaskets guarantee enduring reliability, system efficiency, and operational safety. Selecting the right spiral wound gasket guarantees consistent performance, minimizes maintenance needs, and maintains system integrity, even in the most challenging and fluctuating operational settings.