Imagine an electric vehicle speeding down a mountain road without making any noise, its battery pulsing with carefully planned power, its systems shielded from heat, moisture, and vibration by something far less obvious than shields: gaskets. The electric vehicle (EV) revolution is made possible by these unseen but vital sentinels. Gaskets are more than just sealing devices; they are defenders of efficiency, safety, and dependability as EVs redefine mobility in the high-voltage world of electric mobility, where even a minor failure can spiral into a system-wide problem. They are essential to making sure EVs run well in every situation, from battery packs to powertrain electronics and thermal management systems.

The new demands of electrification

Compared to conventional internal combustion engine vehicles, electric vehicles (EVs) have distinct gasket design issues. Among these is the requirement for high voltage insulation in battery modules and power electronics to avoid electrical arcing and short circuiting. Furthermore, as components are subjected to extreme heat from inverters, motors, and batteries in addition to abrupt cooling cycles, thermal management becomes crucial. Since EV gaskets come into contact with coolant fluids, flame retardants, and possible leaks from lithium-ion battery electrolytes, they must also have strong chemical resistance. Another important consideration is lightweight design; each gram adds to energy efficiency, which leads to the usage of high-performance, lightweight gasket solutions. Furthermore, gaskets occasionally need to function as shields against electromagnetic interference, due to the growing complexity of EV electronics.

Material innovations

Gasket materials are being significantly innovated to keep up with the rapidly changing EV technology. For high-voltage applications, low-permeability elastomers like FFKM (perfluoroelastomers) provide unmatched resistance to permeation, heat degradation, and chemical assault. Another development is thermally conductive gaskets, which are intended to help dissipate heat in addition to sealing, particularly in battery modules and power electronics. These days, some gasket materials have the ability to mend themselves. By recovering from microcracks brought on by constant heat cycling, these polymers can prolong their useful lives. Gasket development is also being impacted by sustainability, as recyclable and environmentally friendly materials are becoming more and more popular in line with the EV industry’s drive for greener manufacturing.

Design considerations

In order to build gaskets in EVs effectively, a number of engineering criteria must be carefully considered. In order to guarantee that the material keeps its shape and sealing ability under extended stress, compression set resistance is crucial. The gasket’s hardness needs to be carefully regulated; too soft a material could let leaks through, while too firm a material might not compress sufficiently to create a good seal. Standards for flammability must also be taken into account. FMVSS, UL 94, and other fire safety certifications must be met by the materials. Gaskets and the parts they shield are increasingly being created together. Tailored bolt-hole designs, different thicknesses, and custom geometries are typical. During the design stage, sophisticated simulation technologies such as Finite Element Analysis (FEA) are used to forecast how gaskets will function in actual situations.

Other factors

- Battery packs

Any EV’s battery system, which consists of densely packed, high-capacity energy storage modules, is its central component. Since lithium batteries are extremely vulnerable to water and particulate contamination, these enclosures must be completely protected from both moisture and dust. IP67 and IP68-rated gaskets are commonly used to offer complete ingress protection in order to guarantee endurance. Cycles of charging and discharging may cause pressure to accumulate inside the battery enclosure, requiring gaskets with venting membranes. These membranes let gases out while keeping impurities out. Furthermore, thermal barrier qualities are essential; in the event of cell failure, fire-retardant gaskets composed of materials like silicone foams or mica composites are utilized to contain and limit the spread of thermal events. PTFE and expanded PTFE for chemical resistance and gas-tight performance, silicone foams for cushioning and heat resistance, and UL94 V-0 rated elastomers to satisfy strict flame retardancy requirements are common materials used in battery pack gaskets.

- Thermal management systems

Liquid cooling systems are used in electric vehicles to control the temperature of the motors, inverters, and battery packs. Gaskets for these systems must be able to withstand exposure to different coolant fluids, such as dielectric fluids or glycol-water mixes. Rapid heating and cooling, or pressure cycling, puts extra strain on gaskets, which need to remain intact in the face of change. Seal performance is further hampered by vibration from moving vehicles or uneven roads, particularly at pipe and flange joints. Because of their resilience to chemicals and resilience to high temperatures, rubber elastomers like EPDM and FKM are frequently utilized in these systems. For higher-pressure areas, spiral-wound gaskets can be used to provide a reliable, long-lasting seal. The ultimate objective is to accommodate the expansion and contraction brought on by heat variation while preventing leaks that could impair system performance or harm vital components.

- Electronics and power conversion units

EV operation depends on power electronics such DC-DC converters, inverters, and onboard chargers. Because these devices produce a lot of heat and run at high voltages, gasket performance is essential for dependability and protection. Sensitive electronics must be sealed against the elements to keep moisture and dust out. Additionally, gaskets need to provide dielectric isolation to stop current leaks, guaranteeing component lifespan and safety. Furthermore, in tightly packed systems, protecting against electromagnetic interference is frequently required to maintain signal integrity. Graphite-filled PTFE, which provides superior electrical isolation at high temperatures, silicone gels for potting or encapsulating sensitive areas, and conductive elastomers that give both EMI shielding and sealing flexibility are among the materials utilized in these applications. By guaranteeing consistent performance, these gaskets increase the lifespan of electronics even under harsh operating conditions.

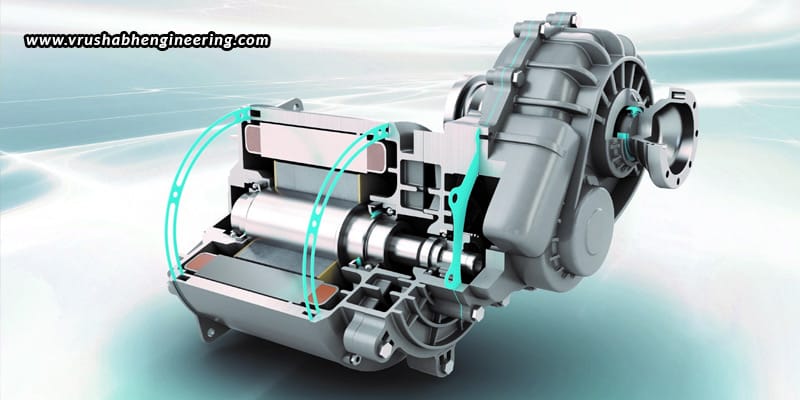

- Drive units and motor housings

Compact systems that are subject to significant mechanical and thermal loads are electric car drive units, which comprise the motor, inverter, and transmission. Exceptionally resilient sealing systems are required due to vibration and torque forces. Gaskets in models with oil-lubricated gearboxes must also be resistant to lubricants and transmission fluids. These parts also see a lot of thermal cycling, thus materials that can tolerate repeated heating and cooling without degrading are required. Metal-reinforced rubber gaskets are the preferred sealing solution for drive units because they provide a good mix of strength and flexibility. For complex part geometries, liquid gaskets or form-in-place (FIP) gaskets are used, enabling the creation of unique sealing profiles. For precise applications, custom-moulded silicone seals are very commonly utilized, guaranteeing a dependable fit and top performance.

- Safety and regulatory requirements

Strict regulatory requirements are placed on gaskets in electric vehicles to guarantee their dependability and security. It is frequently required to adhere to UL 94 V-0 for flame retardance. To protect components from exposure to the environment, further ingress protection ratings, such as IP67 and IP68, as defined by ISO 20653 and IEC 60529. Additionally, automakers apply their own strict EV-specific requirements that address overall performance, emissions, dielectric strength, and material selection. In EV gasket testing, the component is tested in harsh environments, such as compression set testing, chemical exposure, thermal shock, dielectric breakdown, and flammability. These exacting procedures aid in confirming that gaskets will remain intact for the duration of a vehicle’s life.

Partnering with the right supplier

Working together with seasoned gasket manufacturers is essential for navigating the intricate and constantly changing EV industry. Leading gasket producers in India have met this issue by providing scalable production capacity, engineering support, and cutting-edge materials. Customized battery pack sealing formulations, materials with EMI and RFI shielding qualities, flame-retardant solutions, and systems that combine venting and sealing in one component are all available from a top-notch gasket provider for EV applications. Vrushabh Engineering stands out among the industry leaders for providing innovative gasket solutions for a variety of applications. Vrushabh Engineering is one of the top gasket manufacturers in India that guarantees long-term dependability and safety with its robust skills, precision manufacturing, and dedication to quality.